This type of hoist system is usually only used in low-rise buildings, typically up to six stories high or to transport extremely heavy loads Hydraulic elevators are lifted by pistons from below. These elevators require more energy to operate than other elevator models and, due to the introduction of machine-room-less elevators with high-efficiency machine and drives, have largely been replaced in the elevator market.

This type of elevator operates via a pulley system, using steel ropes or belts and a counterweight to move the cabin up and down. There are two types of traction elevators: Gearless Traction and Geared Traction. Gearless traction elevators are the more advanced solution, with a wheel attached directly to the motor and counterweights are used to operate the hoisting system. Geared traction uses a gearbox to turn the hoisting sheave and lift the elevator. These systems are typically slower than gearless systems. Overall, traction elevators are typically more energy efficient and provide a smoother and quieter ride for passengers.

Overall, traction elevators are typically more energy efficient and provide a smoother and quieter ride for passengers. Most modern elevators are typically gearless traction, which is considered the most energy and space efficient solution available.

Advancements in elevator technology have made it possible to eliminate the need for a traditional machine room to house elevator components. There are two main options in this regard:

MRL systems can be either traction or hydraulic in nature. These innovative systems eliminate the necessity for a dedicated machine room by incorporating more compact hoisting sheaves. Instead, the elevator's machinery is positioned directly within the elevator hoistway. This design maximizes the efficient utilization of space within the building's overall layout.

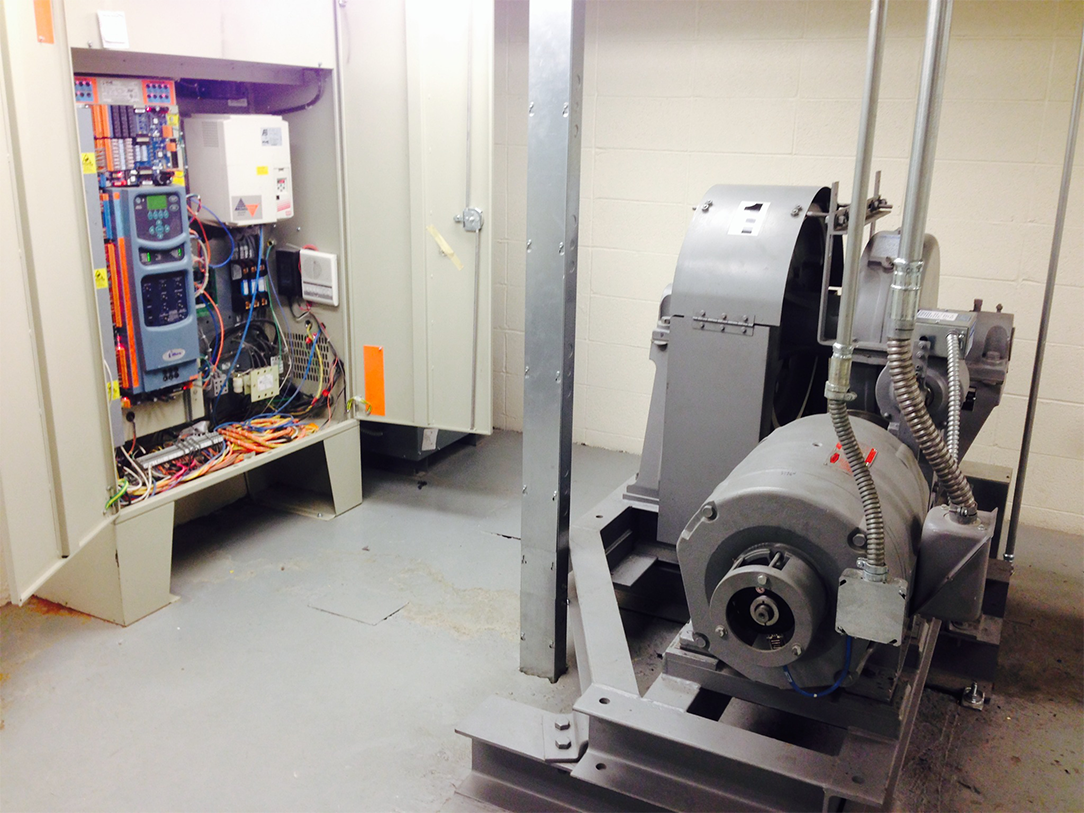

MR systems are available in both traction and hydraulic configurations. In traction elevators, the machine room is typically situated above the elevator hoistway. However, it's worth noting that the machine room can also be positioned at the bottom of the hoistway or in a room adjacent to the elevator bank, offering some flexibility in its placement.

These advancements in elevator technology provide architects and builders with greater flexibility in designing spaces, as the need for a traditional machine room is no longer mandatory.

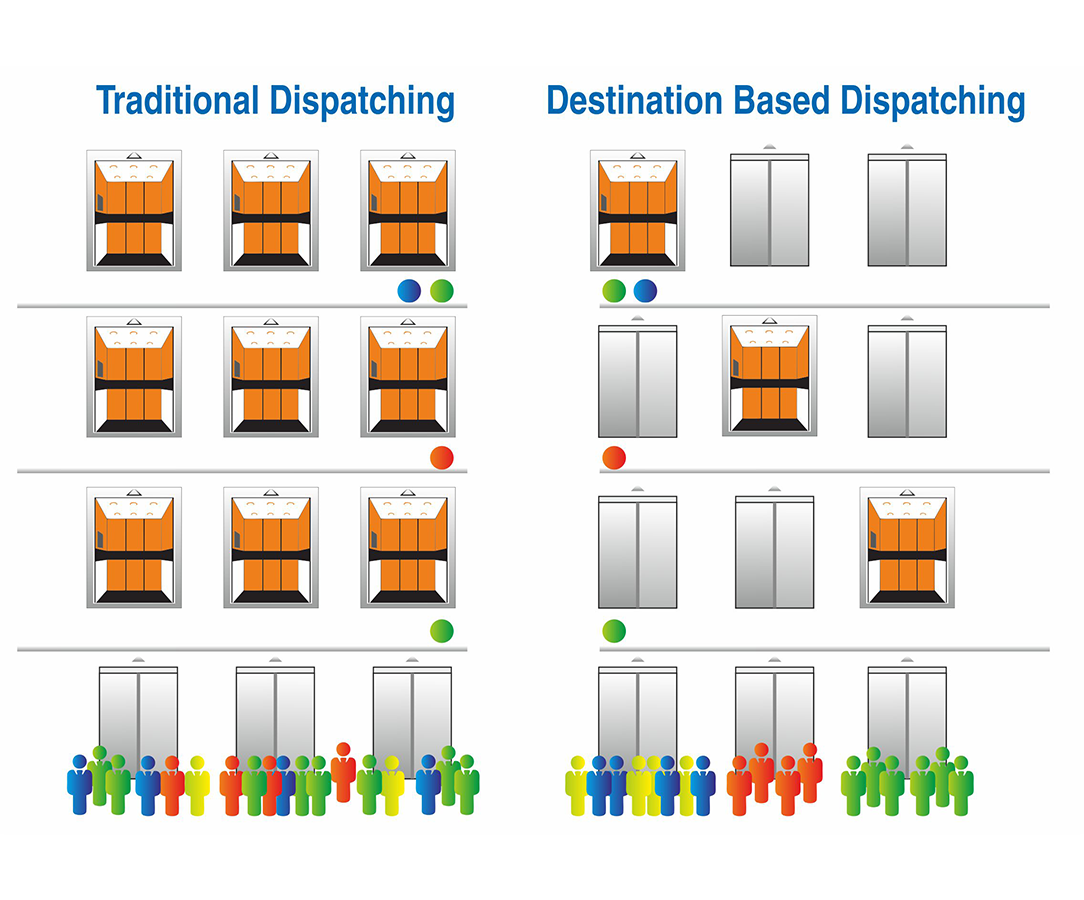

DBD has an high-end group dispatcher software calculates the floors, passengers, traffic condition and all others elements constantly. After the passenger pressed the target floor on the DID ( lobby boost system), the DBD system will assign the passenger to one of the car that can bring the passenger up within a shortest period of time. It dispatches the passengers into different groups and prevents traffic congestion.

The DBD systems has been installed at various job sites, and sufficiently functioned as reducing the time to destination. In addition, DBD can be an affordable solution for high-speed group control and security solution. Passenger use security card to register floor at turnstile, as well as accessing the kiosks at every floor for identity verification. The user-friendly built-in security system can also adapt to the dynamic building traffic conditions and integrated fully with the building security system.

Elevators prioritize safety and quality assurance in product and service delivery. Rigorous testing, adherence to safety standards, meticulous maintenance, and expert personnel ensure uninterrupted functionality. Every aspect, from design to installation, underscores a dedication to excellence, ensuring trust through paramount safety and quality."